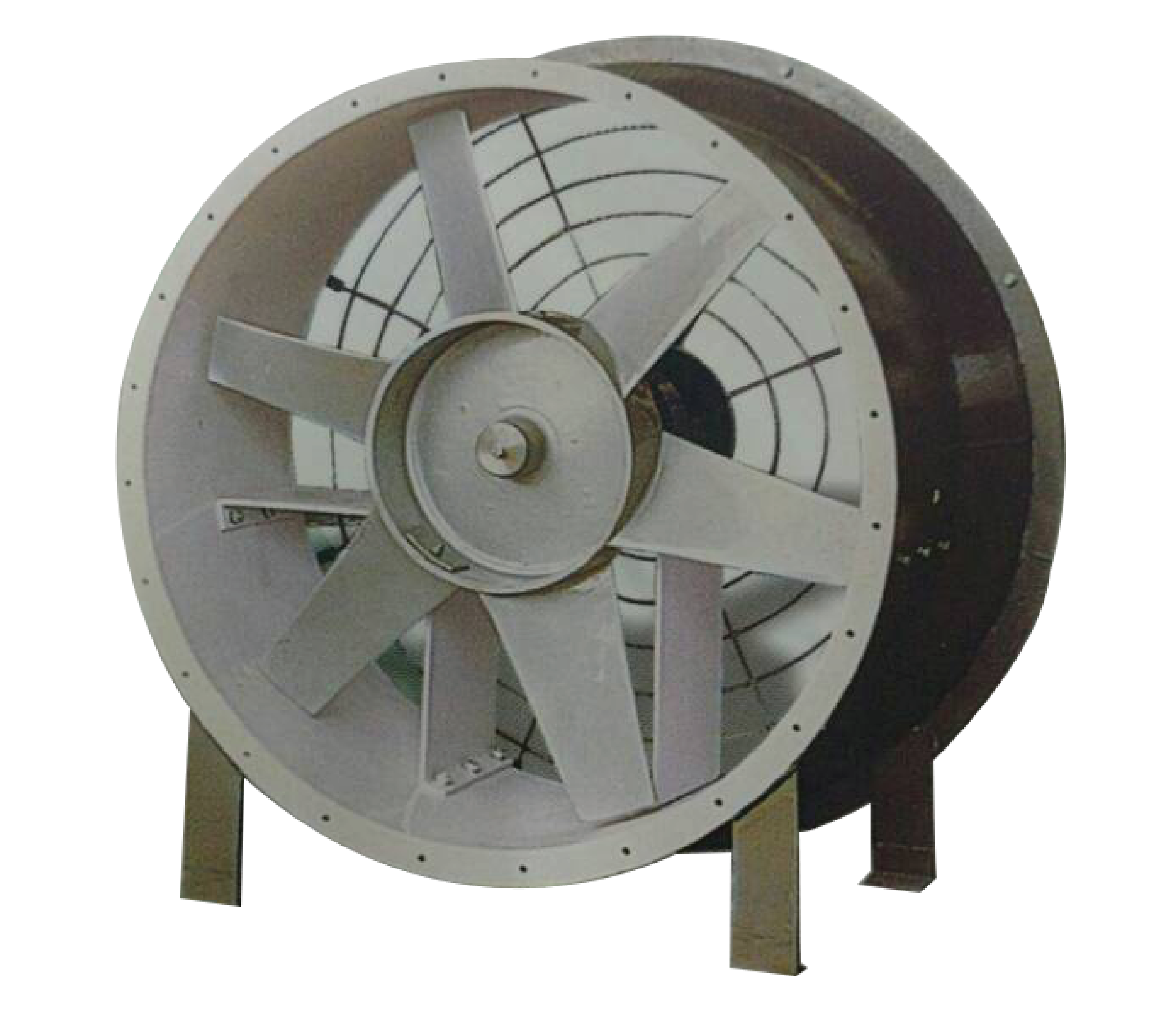

Axial Flow Fan

AXIAL FLOW FAN

Appolo Axial Flow Fan

- Suitable for withering troughs.

- Aero-dynamically designed and dynamically six bladed aluminum impeller for power economy and low noise level.

- Available with both fixed and adjustable blades.

- Impeller directly mounted on motor shaft.

- Heavy duty vibration frees casting.

Performance Characteristics :

The impeller blades and the hub are made of high grade cast aluminum alloy (IM-6 of BS 1490/IS 617 GV 6700) the assembled rotor is dynamically balanced before mounting directing on the motor shaft and tested for vibration, noise level, air delivery and static pressure. The cylindrical casing is fabricated of 3mm thick M.S. sheet (as per IS – 1079/15), with the motor base plate of 6/8 mm thickness, welded inside at correct height to ensure its concentrate with the impeller axis when assembled with motor. Flanges of 50 mm height are provided at both the ends with 12 mm diameter holes for connection to the duct works leading to the transition piece before the air plenum chambers of the equipment to suit the desire working mode (suction or blowing) like in the case of the Withering Trough. Mounting legs are fitted for use if needed. Protection Guard, fabricated of weld mesh on a circular metal frame is bottled at the free end of the casting to suit the desired working mode (suction or blowing).

Technical Specifications:

MODEL | Impeller Diameter | Motor- 3 ph 415 V/50hz | Air Floor Rate (Air Delivery) | Disch. Air velocity | Static Pressure | Total Pressure | Shaft BHP | ||||||

| Inch | mm | hp | rpm | Cfm | M3/hr | Ft/min | m/sec | inch | mm | inch | mm | hp |

AAF – 403 | 40 | 1016 | 3 | 960 | 19000 | 32306 | 2178 | 11.1 | 0.5 | 12.7 | 0.78 | 19.9 | 2.6 |

AAF – 483 | 48 | 1219 | 3 | 960 | 23500 | 39957 | 1871 | 9.5 | 0.5 | 12.7 | 0.71 | 18.0 | 2.9 |

AAF – 485 | 48 | 1219 | 5 | 960 | 29500 | 50159 | 2349 | 11.9 | 0.5 | 12.7 | 0.83 | 21.1 | 4.3 |

AAF – 487 | 48 | 1219 | 7.5 | 960 | 37000 | 62912 | 2946 | 15.0 | 0.5 | 12.7 | 1.02 | 25.09 | 6.6 |

AAF – 541 | 54 | 1372 | 10 | 960 | 48000 | 81615 | 3020 | 15.3 | 0.5 | 12.7 | 1.05 | 26.6 | 8.8 |